Case Studies

Published on 20 May 2025

James Willoughby

How drones are transforming the electricity sector

From powerline inspection through to substation management, find out how drones are revolutionising the electricity industry.

In-depth look at how drones are transforming the electricity industry - from powerline inspection to substation management - using datasets collected by heliguy™ and our clients;

Drones increase safety and efficiency, gather high-quality data, and help the sector meet its sustainability targets;

Benefit from versatile data, including photogrammetry, LiDAR, thermal, and RGB visual. Find out which data-capture method is best for your applications;

Comparison between piloting a drone on-site and remote and automated drone-in-abox deployments;

Learn about the best DJI drones and cameras for inspection and surveying across the electricity sector.

Managing power infrastructure - from transmission towers to substations - requires regular, accurate inspections.

Traditional methods can be time-consuming, risky, and resource-intensive. Drones offer a smarter solution.

Equipped with advanced tools like LiDAR, thermal imaging, RGB cameras, and photogrammetry, drones deliver fast, safe, and detailed assessments across even the most challenging environments.

Whether flown by skilled pilots or deployed autonomously through drone-in-a-box systems like the DJI Dock ecosystem, drones are transforming how utilities monitor and maintain their networks.

In this article, we explore how drone technology is redefining inspection standards across the electricity sector, helping providers save time, cut costs, and make better decisions.

Benefits of drones in the electricity sector

Drones offer distinct advantages. These include:

1: Enhanced safety

Working around live power lines, high-voltage substations, or scaling transmission towers is inherently dangerous.

Drones remove the need for manual inspections in hazardous zones.

With remote piloting and automation, field engineers can remain safely on the ground while still gathering all the necessary data.

2. Increased efficiency

Drones drastically cut inspection times - covering vast networks of pylons, substations, or overhead lines in hours instead of days.

Whether deployed by a pilot or autonomously via a drone-in-a-box system, they streamline workflows, reduce or even remove downtime, and optimise resource allocation.

3. High-precision data collection

The range of sensors available for drones allows for multi-dimensional insights:

RGB (Visual) Cameras: Capture high-resolution images for visual condition assessments.

![]()

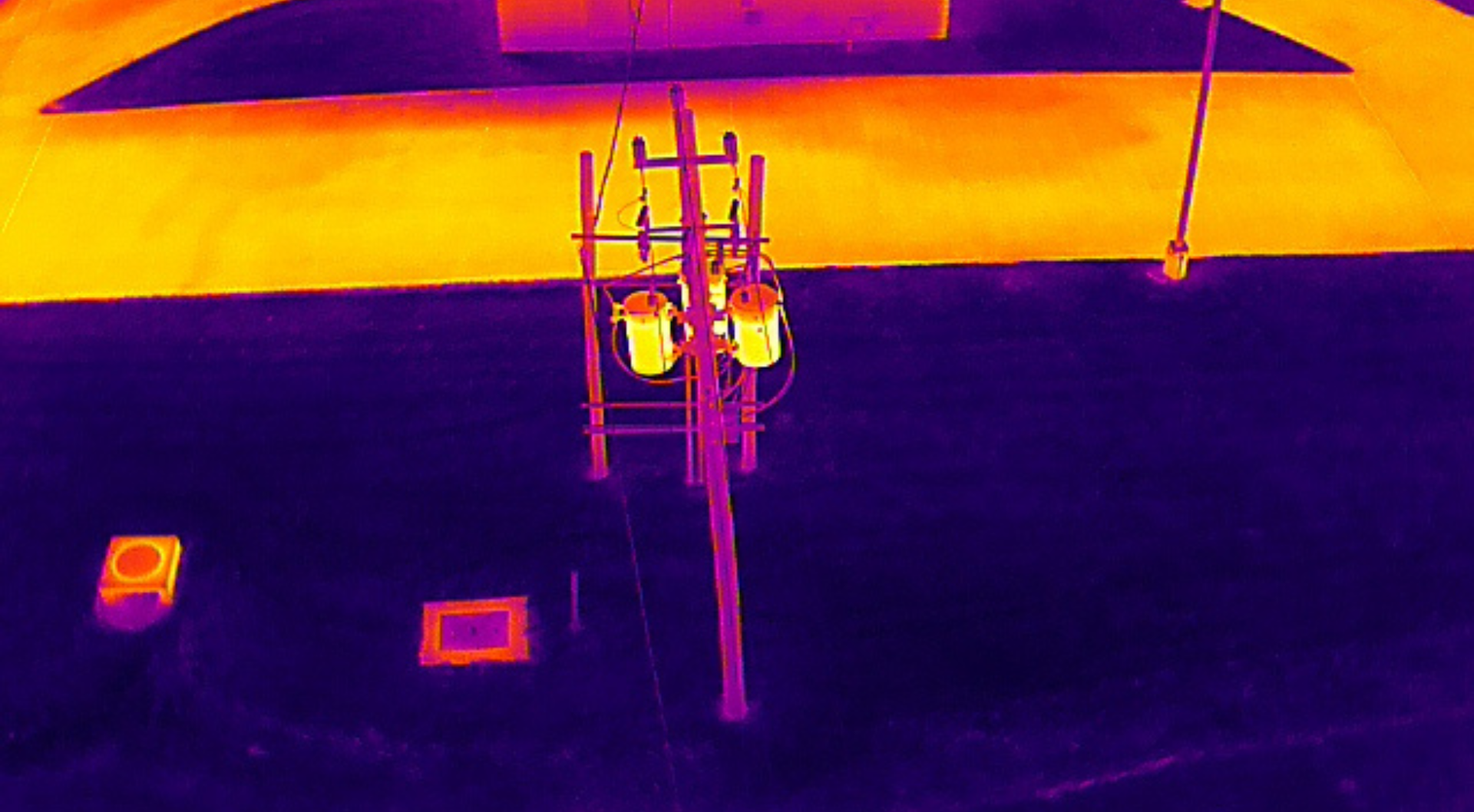

Thermal Imaging: Detect overheating components, faulty insulators, or hotspots invisible to the naked eye.

![]()

Photogrammetry: Generate detailed 3D models and orthomosaics for inspection and asset-management purposes.

![]()

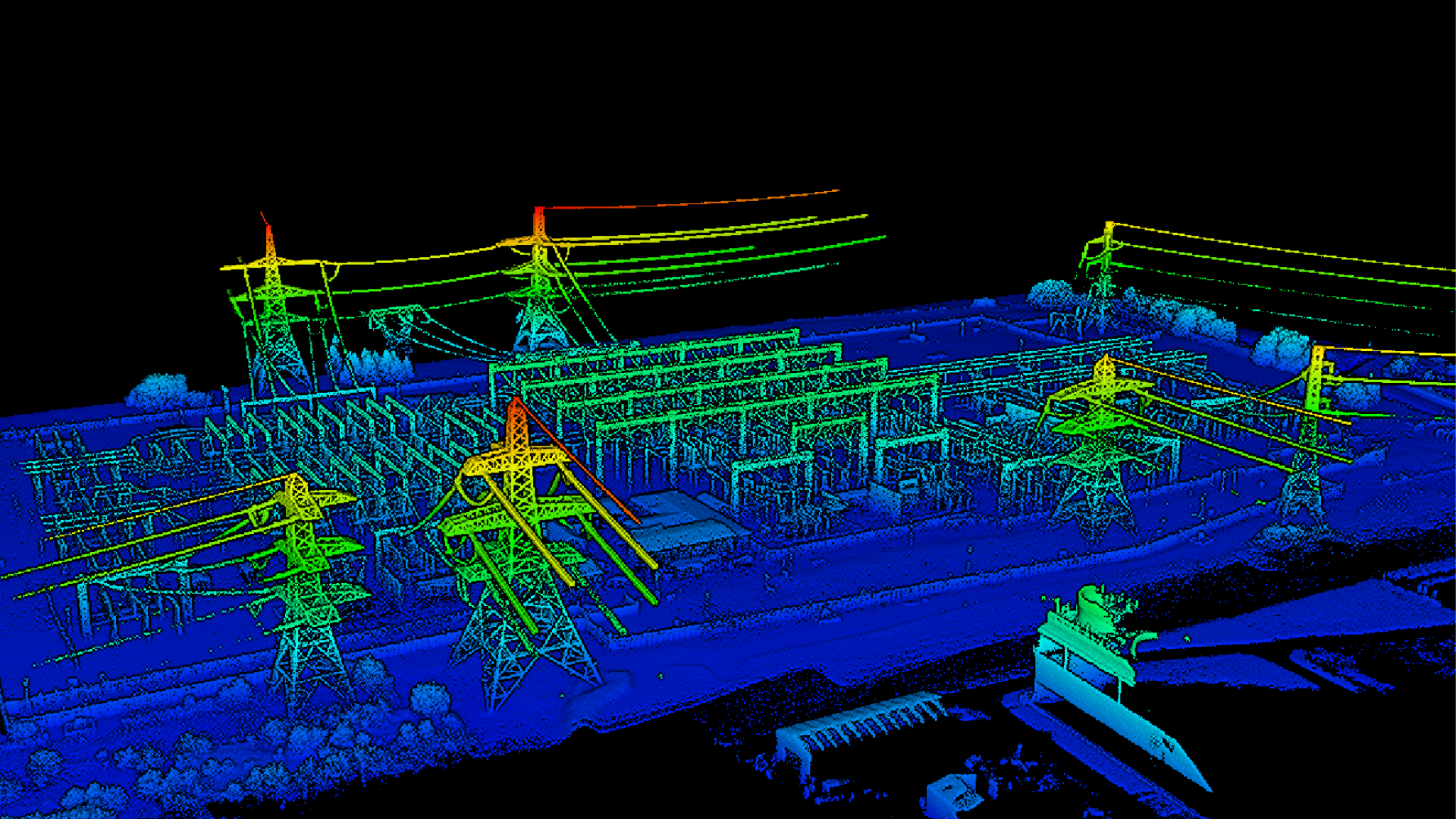

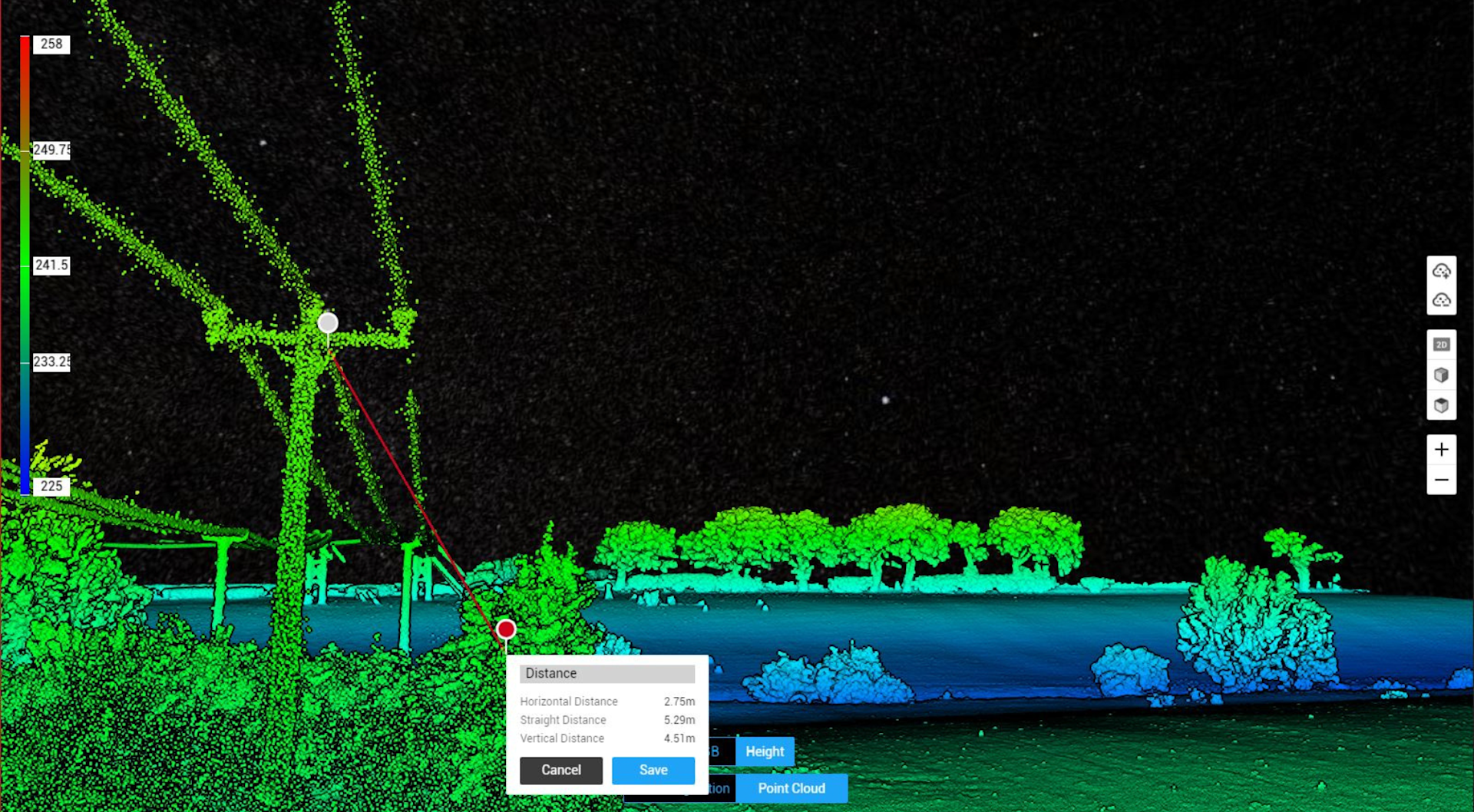

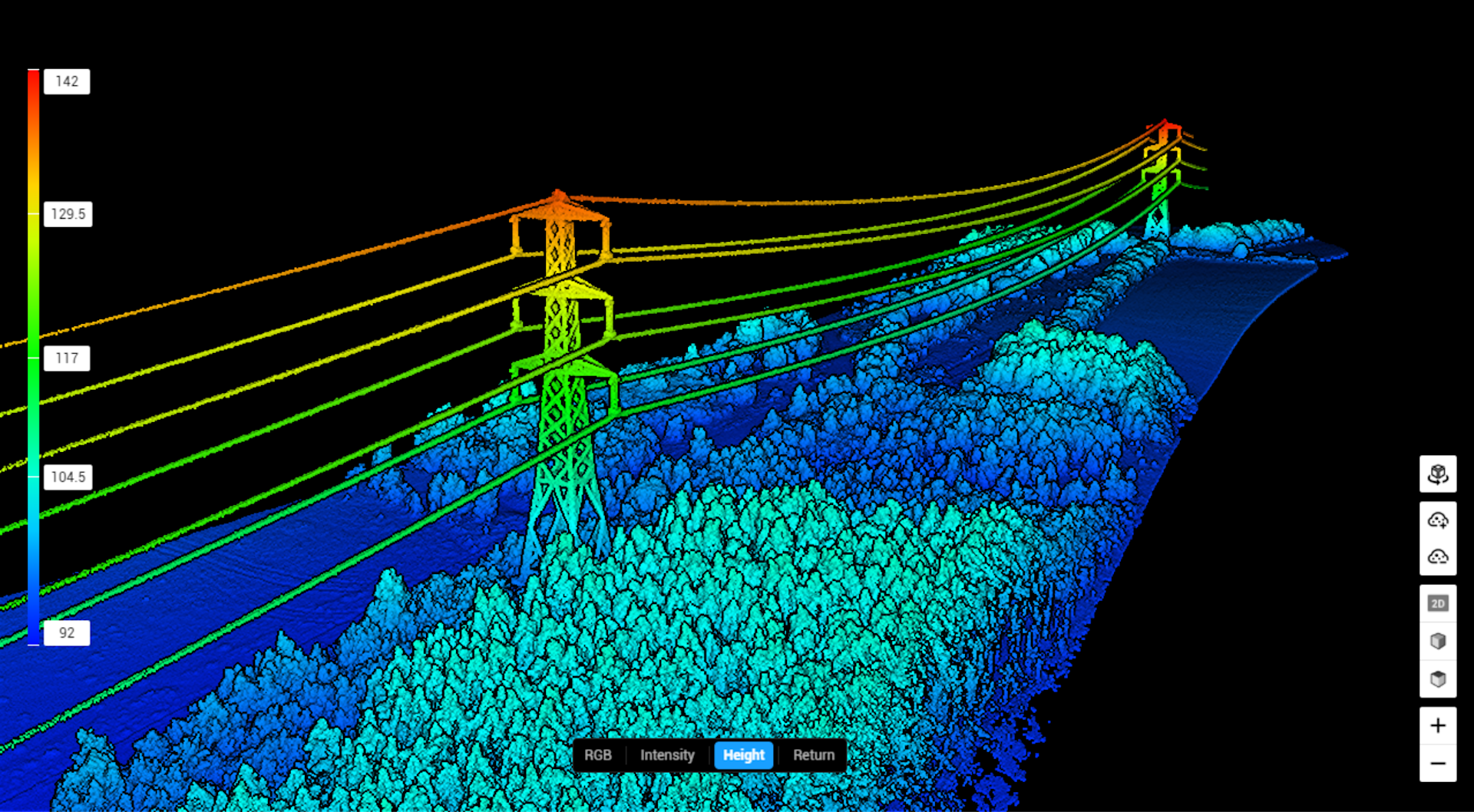

LiDAR: Capture accurate, high-density point clouds for structure mapping, clearance analysis, and vegetation encroachment monitoring.

![]()

4. Cost-effectiveness

By minimising man-hours, reducing the need for access equipment (cranes, helicopters), and eliminating outages during inspection, drones offer a measurable return on investment.

With fewer boots on the ground, operating costs go down, inspection frequency can go up, and downtime can be cut or even eliminated.

5. Unmatched accessibility

Drones can reach tall towers, remote terrain, or confined substation areas quickly and without the logistical complications of traditional access methods.

They're ideal for covering difficult landscapes or areas affected by weather events or natural disasters.

6: Sustainability

Drones support the electricity sector’s sustainability goals:

Lower carbon footprint than helicopters or truck-based inspections.

Reduced need for physical access to remote locations, preserving sensitive environments.

This was epitomised by heliguy™ client Keltbray, who won the prestigious Green Apple World Environmental Award for cutting carbon emissions by using drones for utility inspection.

7: Scalability

Digital infrastructure enables scalable, data-driven asset management.

As utilities modernise their grid, drones are perfectly aligned with smart infrastructure, IoT, and predictive maintenance platforms - offering real-time insights and long-term digital records.

Technology deep dive: Choosing the right sensor for the job

Drones enable versatile data collection for the electricity sector.

The table below provides an overview of this, exploring the strengths of RGB, thermal, photogrammetry, and LiDAR.

Sensor type | Key uses in electrical infrastructure | Strengths | Limitations |

|---|---|---|---|

RGB cameras | Visual inspections, asset documentation | Affordable, high-resolution | No thermal or depth data |

Thermal | Identifying hot spots, loose connections, load imbalances | Great for fault detection | Low detail; best used with RGB |

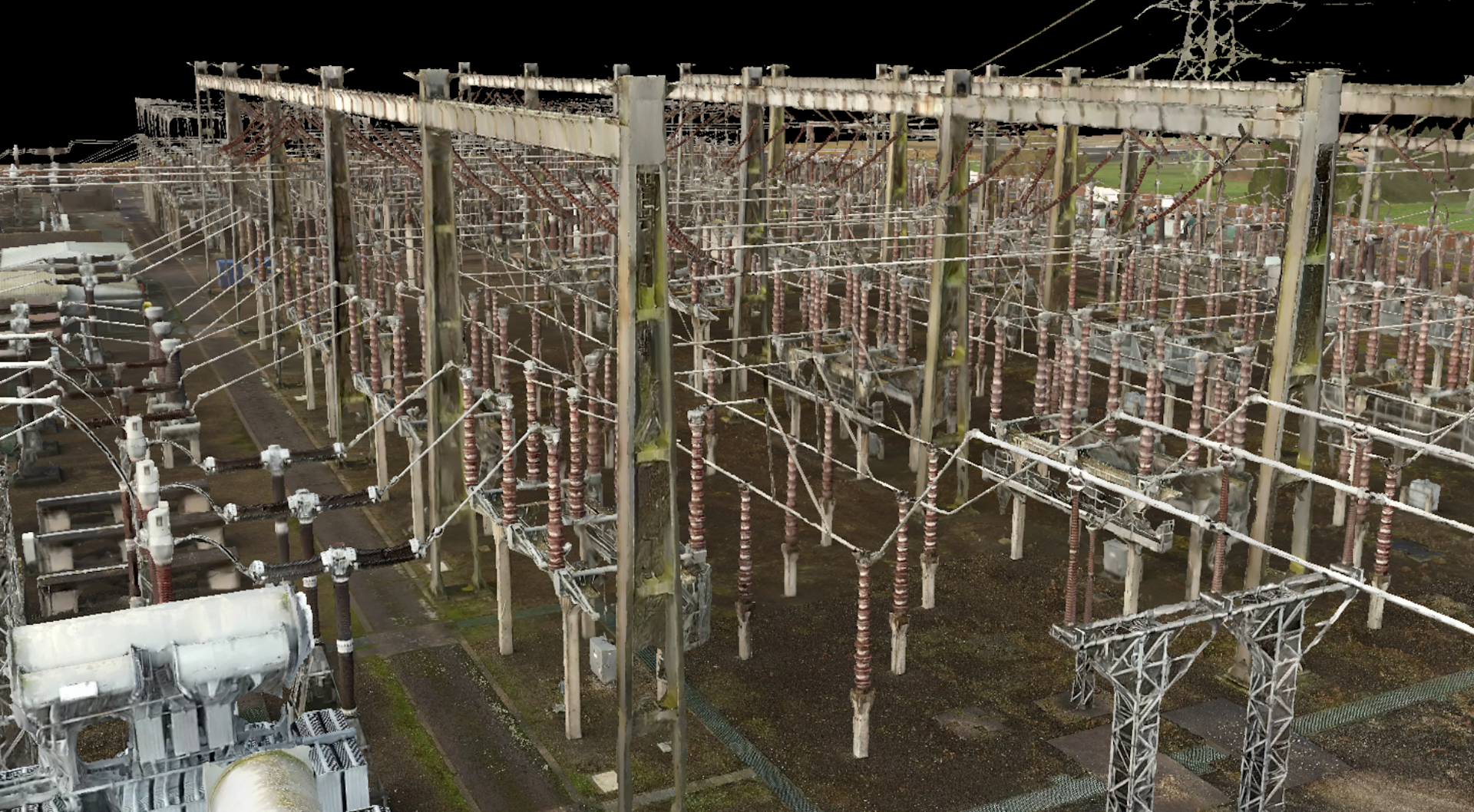

Photogrammetry | 3D modelling of substations, towers | Rich visual context | Less accurate than LiDAR in complex environments |

LiDAR | Structural mapping, clearance checks, vegetation proximity | Precise, handles low-light or cluttered scenes | Higher cost, less visual clarity - although the DJI Zenmuse L2 generates true-colour point clouds for enhanced visualisation |

Drone applications across the power network

Drones benefit applications throughout the power network lifecycle.

1. Drones for Transmission Towers

LiDAR: Measure tower deflection, bolt alignment, and structural integrity.

Thermal: Detect abnormal heating in insulators and conductors.

RGB: Visual crack detection, rusting, or physical damage.

Photogrammetry: Generate 3D models for maintenance planning and documentation.

2. Drones for Power Lines and Overhead Cables

LiDAR: Map cable sag and measure clearance over roads and vegetation.

Thermal: Identify resistive hotspots or damaged connectors.

Visual: Spot bird nests, corrosion, or damaged fittings.

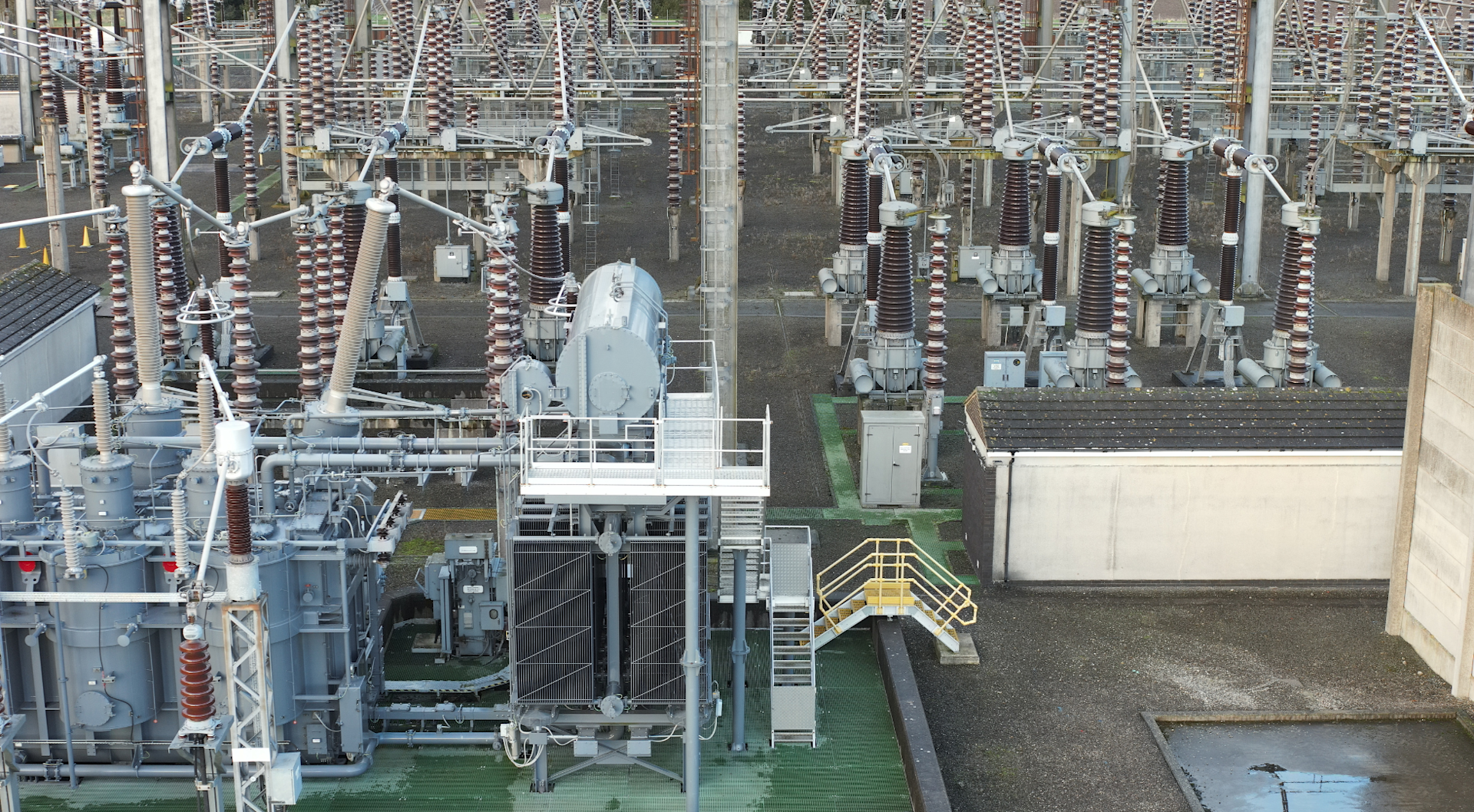

3. Drones for Substations

LiDAR: Create digital twins, identify spatial anomalies, and plan upgrades.

Thermal: Monitor transformers, circuit breakers, and switchgear.

Photogrammetry: Map layouts for GIS integration.

RGB: Track rust, oil leaks, or external degradation.

Drone deployment models: Piloted vs remote and automated systems

When it comes to deployment, two options are available: Pilots on the ground controlling the drones, or drone-in-a-box systems for remote and automated missions.

Piloted systems are ideal for flexible, one-off jobs or reactive maintenance, whereas remote and automated systems shine in high-frequency, standardised inspections where consistency, speed, and scalability are key - especially for substations, long transmission corridors, or remote sites.

This table breaks down the two options.

Piloted drone operations | Automated (remote/BVLOS systems) | |

|---|---|---|

Deployment | On-site drone pilot manually controls each mission | Pre-programmed or remotely managed flights with minimal/no on-site staff |

Use-case examples | Ad-hoc inspections, storm damage assessment, construction checks | Routine monitoring, daily/weekly automated scans, rapid-response alerts |

Responsiveness | Rapid deployment when pilot is available | Instant readiness; can launch on schedule or trigger automatically |

Operational range | Limited to pilot line-of-sight (VLOS) | Extended via BVLOS (beyond visual line of sight), covering remote assets |

Personnel requirements | Qualified drone pilot and possibly observer | Remote operator and backend maintenance technician |

Inspection frequency | Scheduled or reactive (on demand, subject to pilot availability) | High-frequency, repeatable (e.g. daily or hourly) |

Data consistency | Variable depending on pilot skill and weather | High consistency through pre-defined automated flight paths |

Infrastructure needed | Minimal - just pilot and drone | Requires dock system (e.g. DJI Dock), power supply, connectivity |

Setup time | Quick setup, but depends on travel and site access | Always ready to launch; no travel/setup delay |

Cost structure | Lower upfront, higher ongoing labour costs | Higher upfront investment, lower operational costs over time |

Regulatory complexity | Easier to permit (VLOS), but limited in scope | Requires regulatory approvals (BVLOS, remote ops) |

Best for | Flexibility, one-off missions, dynamic environments | Routine monitoring, hard-to-reach assets, high-frequency inspection zones |

heliguy™ offers drone training and support for both types of deployment, including a UK SORA consultancy service to help with remote and automated BVLOS operations.

heliguy™ also has permission to operate DJI Docks BVLOS in an Atypical Air Environment - using this to conduct operations on behalf of clients, or helping organisations obtain their own permissions, or a hybrid pathway which is a combination of the two previous methods. Contact us for more information.

Best DJI drones for the electricity industry

DJI has numerous solutions that are ideal for electricity sector deployment.

DJI Zenmuse L2 (paired with DJI M350 or M300 RTK)

Payload Type: LiDAR + RGB camera.

Key Capabilities: High-accuracy and true-colour point cloud, 5 returns per pulse, real-time point visualisation, Power Line follow functionality.

Best Use Cases: Power line mapping, substation modeling, vegetation encroachment.

The video below shows a dataset collected with the L2 using its Power Line Follow functionality - enabling the drone to automatically identify and track power lines, streamlining this application. Find out more, here.

DJI Zenmuse P1 (paired with DJI M350 or M300 RTK)

Payload Type: Full-frame photogrammetry.

Key Capabilities: 45MP camera, mechanical shutter, interchangeable lenses.

Best Use Cases: High-resolution substation mapping, asset documentation, tower modelling.

This model was captured with the DJI Zenuse P1 and processed through DJI Terra.

Payload Type: Wide-angle mapping camera, plus medium/tele cameras with zoom capability for inspection.

Key Capabilities: Compact, efficient, and cost-effective survey drone with mechanical shutter. Also features Smart 3D Capture for automated data collection.

Best Use Cases: Quick visual surveys, mapping power line routes, general utility asset inspection.

The video below shows a 3D model of a substation created using the DJI M4E's Smart 3D Capture mode - designed to simplify and automate 3D modelling tasks.

Sensor Type: Wide, medium, and tele camera with zoom, plus thermal sensor.

Key Capabilities: Compact, efficient, and cost-effective drone with thermal capabilities.

Best Use Cases: Insulator scans, hot spot detection, nighttime substation checks.

DJI M350 RTK and H30T

Sensor Type: Multi-sensor: Wide, zoom, laser rangefinder, thermal.

Key Capabilities: Long flight time, extreme zoom, thermal and laser range for remote detail capture.

Best Use Cases: Comprehensive tower inspection, fault localisation, long-range power line assessments.

Sensor Type: M4D = automated mapping and inspection drone. M4TD = automated visual and thermal data capture.

Key Capabilities: Fully-automated drone-in-a-box platform for remote operations; weatherproof, deployment. Integrate with LiDAR obstacle module for enhanced detection - particularly useful for operating close to power lines.

Best Use Cases: Routine substation inspections, automated perimeter patrols, remote tower checks.

Summary

Drones are no longer a futuristic option for the electricity sector - they are a proven, evolving necessity.

Whether via expert pilots or automated drone docks, these systems deliver unmatched safety, efficiency, and insight across transmission towers, power lines, and substations.

To start and scale your drone operations in the electricity sector, contact heliguy™ today. As a leading DJI dealer, we offer consultancy, support, supply (including rental), training, a dedicated survey department, and repairs.